Lab Design, Setup and Space Planning

Laboratory Design & Space Planning

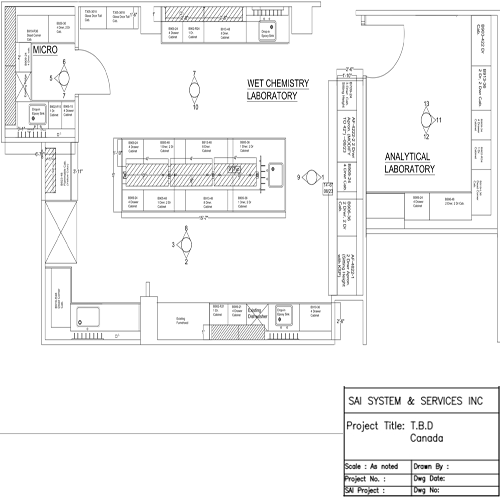

Laboratory space planning requires careful consideration of various factors to ensure efficiency, safety, and compliance with regulations. Here’s a brief summary of points to help you through the process.

- Identify the type of laboratory (e.g., research, clinical, educational).

- For each type of lab, determine the function (e.g., wet chemistry lab, analytical area, microbiology lab, etc.).

- Determine laboratory-specific activities that will take place (e.g., experiments, testing, analysis).

- Calculate the square footage needed based on equipment, lab workstations, storage cabinets, and proper movement.

- It's important to consider future expansion needs. Consider modular lab furniture or mobile furniture and partitions as required.

- Create a logical flow of materials and personnel to minimize bottlenecks.

- Designate areas for different functions (e.g., documentation, packaging, preparation, testing, storage, waste disposal).

- Position laboratory equipment based on usage frequency and workflow.

- Consider power and connectivity needs for each piece of equipment.

- Involve researchers, technicians, and other stakeholders in the planning process to gather input and ensure their needs are met.

- Plan for necessary utilities (e.g., water, electricity, gas, vacuum, compressed air).

- Ensure that outlets and connections are accessible and appropriately placed.

- Plan for temperature and humidity control as needed.

- Consider sustainability measures, such as energy-efficient lighting and HVAC systems.

- Design the space to allow for easy reconfiguration as needs change.

On site delivery & Installation

Scientifically Advanced Interiors has been installing lab casework and fume hoods since almost 15 years across Canada. Following are some key features and benefits of working with SAI Systems.

Experience and Expertise- Approx. 15 years of installation experience helps us to finish any kind of project to customers satisfaction and within schedule.

- We have installed lab casework and fume hoods for almost every projects like Food Manufacturing, Pharma, Hospitals, Research Organizations, Educational institutes etc.

- Our installers are familiar with relevant safety regulations and standards (e.g., OSHA) and we carry necessary liability insurance as required by our customers.

- SAI Systems ensures safety of our installers by providing necessary training and certification required to install lab furniture, fume hoods and lab equipment.

- We have saved thousands of dollars for our customers just with proper planning and scheduling. We provide guidance to our customers for site preparation before lab casework & fume hoods installation. Post installation help follows to ensure smooth completion of project.

- We work with General contracts and your shipping/ receiving team to ensure smooth delivery of goods. Depending on the site conditions items are delivered on tailgate or standard trailers.

Moving or re-designing existing labs

Just like new lab installations, moving or redesigning an existing lab is a significant project that requires careful planning and execution. Local regulations and permits, if required, take time and proper planning will help to complete the project with minimum disruption of your existing operations.

We have helped many customers to modify existing labs. Many of our customers re designed labs to get more storage space in the same square foot of area. Some opted to make changes due to change of equipment designs that evolved over a period of time. Its also very common to re design a lab to get more flexibility and at the same time get a modern look to lab. From initial lab design and planning to scheduling trades, we will help you to ensure your project is completed within schedule and efficiently

Testing of Fume Hoods & Fume Hood Repair

SAI Systems can help our customers with fume hood performance testing meeting ASHRAE 110 standards. We guide our customers with testing procedures, acceptance criteria, frequency of testing and documentations required to be maintained after certification of fume hoods. ANSI/ASHRAE Standard 110 involves 3 important steps.

1. Face Velocity Measurement: Measure the average face velocity at the sash opening.

2. Smoke Testing: Visualize airflow patterns and check for any turbulence or backflow that could compromise safety

3. Containment Testing: To ensure no leakage of hazardous materials beyond acceptable limits, as determined by the testing methods